I have a '51 Cub.

Identify weather you have a 2 or 3 brush generator.

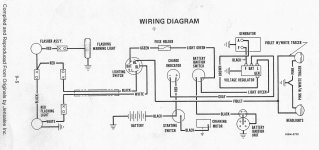

Somewhere through the years there could have been a mismatch of replacement parts.

For example a three brush gen matched to a regulator used with a 2 brush gen.

Or a regulator used where a cutout relay should be used. It could be "Frankensteined".

Do a good visual inspection of the wire harness, especially behind the instrument area.

Look for frayed wires at the terminal ends.

Also those generators won't charge at idle. It's got to be throttle up to charge efficiently. Idle speed and the governor must be adjusted properly as well. (easy)

I'm quite certain the 49 will use a cutout relay, not a voltage regulator.

Or maybe someone along the line replaced the light switch with an incorrect one.

*Check the fan drive belt and make sure it is tight. It has to be since it drives the pulley that drives the generator belt. Belts have to be tight to charge properly. They can't be worn down either or the incorrect size. The top of the belt should be even with the top of the pulley grooves, more or less.

*The grounds are VERY important. Clean where the pos cable connects to the chassis. The generator ground must be good. It grounds through the gen frame and mounting brackets. Mounting bracket to engine block must be clean.

Clean all electrical connections especially the generator terminal stud eyelets, ammeter connections, light switch wire connections, etc.

You can remove the hood/tank assembly to get better access to everything.

I use a modified gas can to set on top of the engine to feed the carb with fuel while the tank is off for engine work. It's so much easier!

You really have to remove the hood to adjust the belts and look things over and to clean Generator grounds. Generator bearings need to be oiled.

You can also remove the generator, take off the back cover and check the brushes. They might be worn down and not make optimum contact to the commutator. Learn how to check the field windings and armature. The generators can be rebuilt. It's important to know the model number. It can be found on the data tag on the housing.