These are snips. The entire interview transcript can be found at the link at bottom of this post.

With the schedule slipping, Williams says a BP manager ordered a faster pace.

"And he requested to the driller, 'Hey, let's bump it up. Let's bump it up.' And what he was talking about there is he's bumping up the rate of penetration. How fast the drill bit is going down," Williams said.

Williams says going faster caused the bottom of the well to split open, swallowing tools and that drilling fluid called "mud."

"We actually got stuck. And we got stuck so bad we had to send tools down into the drill pipe and sever the pipe," Williams explained.

That well was abandoned and Deepwater Horizon had to drill a new route to the oil. It cost BP more than two weeks and millions of dollars.

"We were informed of this during one of the safety meetings, that somewhere in the neighborhood of $25 million was lost in bottom hole assembly and 'mud.' And you always kind of knew that in the back of your mind when they start throwing these big numbers around that there was gonna be a push coming, you know? A push to pick up production and pick up the pace," Williams said.

Asked if there was pressure on the crew after this happened, Williams told Pelley, "There's always pressure, but yes, the pressure was increased."

But the trouble was just beginning: when drilling resumed,

Williams says there was an accident on the rig that has not been reported before. He says, four weeks before the explosion, the rig's most vital piece of safety equipment was damaged.

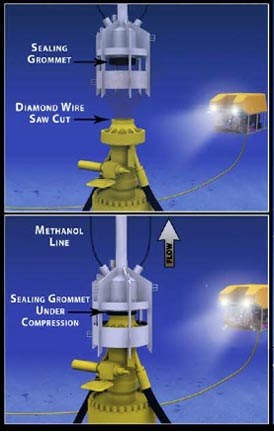

Down near the seabed is the blowout preventer, or BOP. It's used to seal the well shut in order to test the pressure and integrity of the well, and, in case of a blowout, it's the crew's only hope. A key component is a rubber gasket at the top called an "annular," which can close tightly around the drill pipe.

Williams says, during a test, they closed the gasket. But while it was shut tight, a crewman on deck accidentally nudged a joystick, applying hundreds of thousands of pounds of force, and moving 15 feet of drill pipe through the closed blowout preventer. Later, a man monitoring drilling fluid rising to the top made a troubling find.

"

He discovered chunks of rubber in the drilling fluid. He thought it was important enough to gather this double handful of chunks of rubber and bring them into the driller shack. I recall asking the supervisor if this was out of the ordinary. And he says, 'Oh, it's no big deal.' And I thought, 'How can it be not a big deal? There's chunks of our seal is now missing,'" Williams told Pelley.

And, Williams says, he knew about another problem with the blowout preventer.

The BOP is operated from the surface by wires connected to two control pods; one is a back-up. Williams says one pod lost some of its function weeks before.

Transocean tells us the BOP was tested by remote control after these incidents and passed. But nearly a mile below, there was no way to know how much damage there was or whether the pod was unreliable.

To do it BP's way, they had to be absolutely certain that the first two plugs were keeping the pressure down.

That life or death test was done using the blowout preventer which Mike Williams says had a damaged gasket.

Williams' survival may be critical to the investigation. We took his story to Dr. Bob Bea, a professor of engineering at the University of California, Berkeley.

Last week, the White House asked Bea to help analyze the Deepwater Horizon accident. Bea investigated the Columbia Space Shuttle disaster for NASA and the Hurricane Katrina disaster for the National Science Foundation. Bea's voice never completely recovered from the weeks he spent in the flood in New Orleans. But as the White House found, he's among the nation's best, having investigated more than 20 offshore rig disasters.

"Mr. Williams comes forward with these very detailed elements from his viewpoint on a rig. That's a brave and intelligent man," Bea told Pelley.

"What he's saying is very important to this investigation, you believe?" Pelley asked.

"It is," the professor replied.

What strikes Bea is Williams' description of the blowout preventer. Williams says in a drilling accident four weeks before the explosion, the critical rubber gasket, called an "annular," was damaged and pieces of it started coming out of the well.

"According to Williams, when parts of the annular start coming up on the deck someone from Transocean says, ‘Look, don't worry about it.' What does that tell you?" Pelley asked.

"Houston we have a problem," Bea replied.

Here's why that's so important: the annular is used to seal the well for pressure tests. And those tests determine whether dangerous gas is seeping in.

"So if the annular is damaged, if I understand you correctly, you can't do the pressure tests in a reliable way?" Pelley asked.

"That's correct. You may get pressure test recordings, but because you're leaking pressure, they are not reliable," Bea explained.

Williams also told us that a backup control system to the blowout preventer called a pod had lost some of its functions.

"What is the standard operating procedure if you lose one of the control pods?" Pelley asked.

"Reestablish it, fix it. It's like losing one of your legs," Bea said.

"The morning of the disaster, according to Williams, there was an argument in front of all the men on the ship between the Transocean manager and the BP manager. Do you know what that argument is about?" Pelley asked.

Bea replied, "Yes," telling Pelley the argument was about who was the boss.

In finishing the well, the plan was to have a subcontractor, Halliburton, place three concrete plugs, like corks, in the column. The Transocean manager wanted to do this with the column full of heavy drilling fluid - what drillers call "mud" - to keep the pressure down below contained. But the BP manager wanted to begin to remove the "mud" before the last plug was set. That would reduce the pressure controlling the well before the plugs were finished.

Asked why BP would do that, Bea told Pelley, "It expedites the subsequent steps."

"It's a matter of going faster," Pelley remarked.

"Faster, sure," Bea replied.

Bea said BP had won that argument.

"If the 'mud' had been left in the column, would there have been a blowout?" Pelley asked.

"It doesn't look like it," Bea replied.

To do it BP's way, they had to be absolutely certain that the first two plugs were keeping the pressure down. That life or death test was done using the blowout preventer which Mike Williams says had a damaged gasket.

Investigators have also found the BOP had a hydraulic leak and a weak battery.

"Weeks before the disaster they know they are drilling in a dangerous formation, the formation has told them that," Pelley remarked.

"Correct," Bea replied.

http://www.cbsnews.com/stories/2010/05/16/60minutes/main6490197.shtml?tag=contentMain;contentBody

fair use applies